#Lights out manufacturing full#

The vertical and horizontal data integration of Industry 4.0, which is the precondition for nearly full automation, and hard to realize. Artificial intelligence and machine learning, powering the systems, optimization, and other technologies. Analytics, visualization, and automated decisions based on big data, leveraged in real-time. You also need robots (advanced robotics essentially being about autonomous and collaborating industrial robots). You can imagine that without loads of sensors and quite some IoT technologies (and the traditional supporting technologies, connectivity, and systems) lights-out factory setting wouldn’t be possible. One could say that the other stages of Industry 4.0, as a vision, pave the way for ‘dark’ environments.

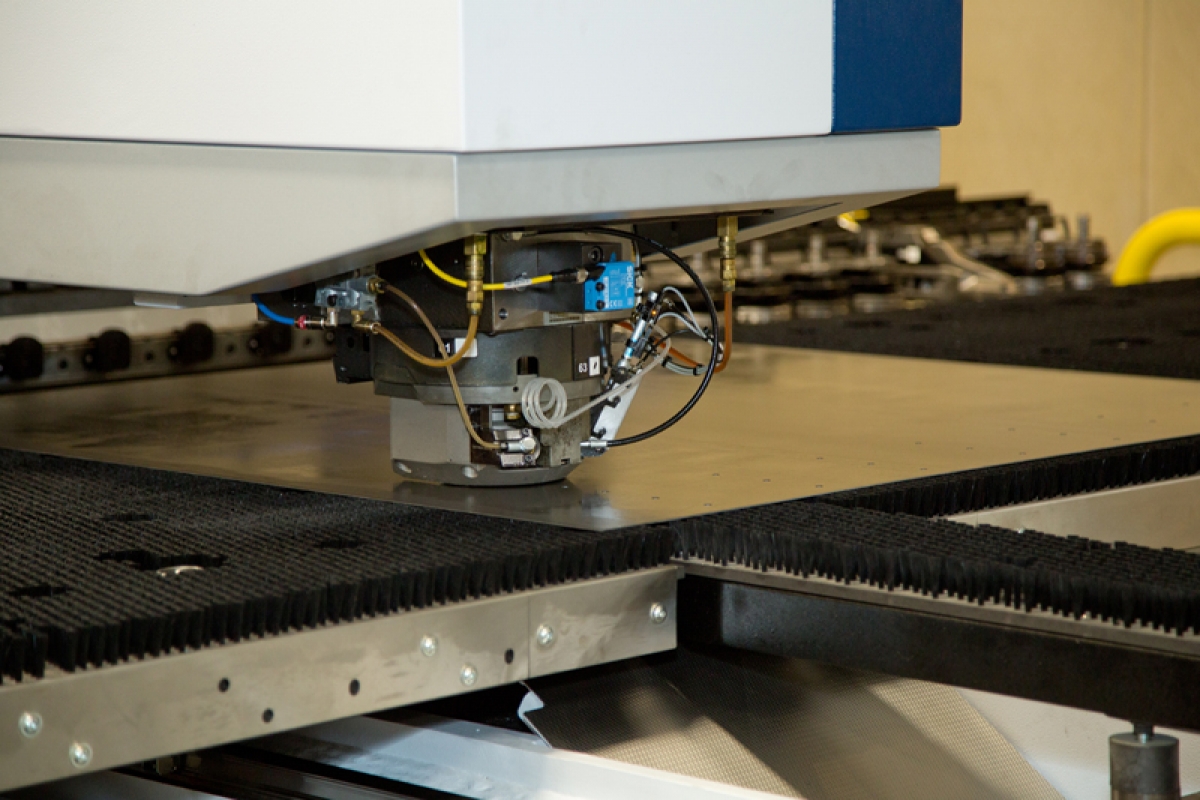

In a lights-out environment, the manufacturing process is fully automated, with minimal human intervention required to run day-to-day operations. There are examples (more below), but there are also failed attempts, and not everyone is convinced. The reality is that we’re entering a situation whereby lights-out environments requiring minimal human intervention come more in reach in some areas and specific cases. As the name indicates, lights-out manufacturing is about automated, autonomous manufacturing processes with the lights and more (e.g., heating) off since, in theory, extremely little human intervention is needed. It approaches the older dream/vision of lights-out manufacturing in its original meaning (as a methodology or even philosophy). Lights-out manufacturing and the stages of industrial transformation The exact same movement towards semi-autonomous or autonomous capabilities, requiring no or little human intervention, is also present in Logistics 4.0.

That stage brings us closer to a wholly automated value chain and self-optimizing, autonomous systems, processes, and manufacturing, in other words: autonomy and independence on, among others, the level of operations. Among the elements in the fourth stage is a further shift to autonomous or semi-autonomous action and machines. The journey of Industry 4.0 has a staged industrial digital transformation approach with typically four stages. Several drivers, including the COVID-19 pandemic, accelerate the adoption of lights-out settings, with some industries moving faster to ‘dark factory environments.’ The concept of lights-out automation and lights-out manufacturing or ‘dark manufacturing’ isn’t new and is closely related to more mature stages of Industry 4.0.

0 kommentar(er)

0 kommentar(er)